Redesigning the pot still

Owning every bit of the process has been important to us, so designing our own stills was the logical place to start.

VITRIOL 1 and 2 our legacy stills

It's best to let Eric, who designed the original geodesic still take over the explanation of the naming of the stills..

“Visita Interiora Terrae Rectificando Invenies Occultum Lapidem" is the meaning of the alchemical acronym V.I.T.R.I.O.L.

Translated from Latin: “Visit the interior of the earth and by rectifying (purifying) you will find the hidden (philosopher's) stone.”

The motto was first published by the 15th Century alchemist Basilius Valentinus, appearing in L’Azoth des Philosophes, and is the search for the philosopher stone, turning base products into gold, which is what we are doing....basically.

fireside plans

scratch built

Designing the pot stills from scratch in Autocad. The brief was maximum copper contact, with high internal reflux. The flat panels of the geodesic allow just that, creating a refined spirit.

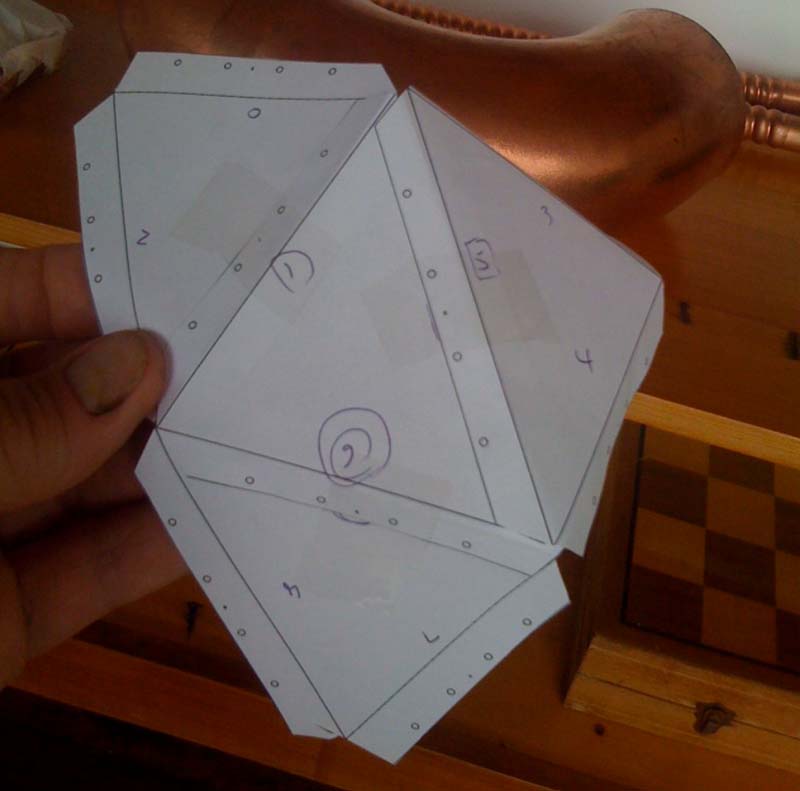

paper model

each piece of the puzzle

individually numbered and bent to fit. Making a paper model first to proof concept.

50 piece jigsaw

spirit still

Eric assembling the base of the spirit still. We cut the panels on a water jet then hand bent the tabs before rivting them and welding the seams.

halves awaiting assembly

joining the halves

would prove the hardest part. The inital idea to allow easy cleaning the still was make in 2 sections. Heat deformity and gasket material would prove tricky....

from surgery to welding

a steep learning curve

Mark welding the spirit still stand. The project was a proof of concept, but VITRIOL 1 is still standing outside the distillery door.

ready for fittings

the completed still

Richard contemplating next steps, electrical fittings and hydralics.

sustainability

direct fire heating elements

PID controlled heating elements are swappable for easy cleaning and replacement.

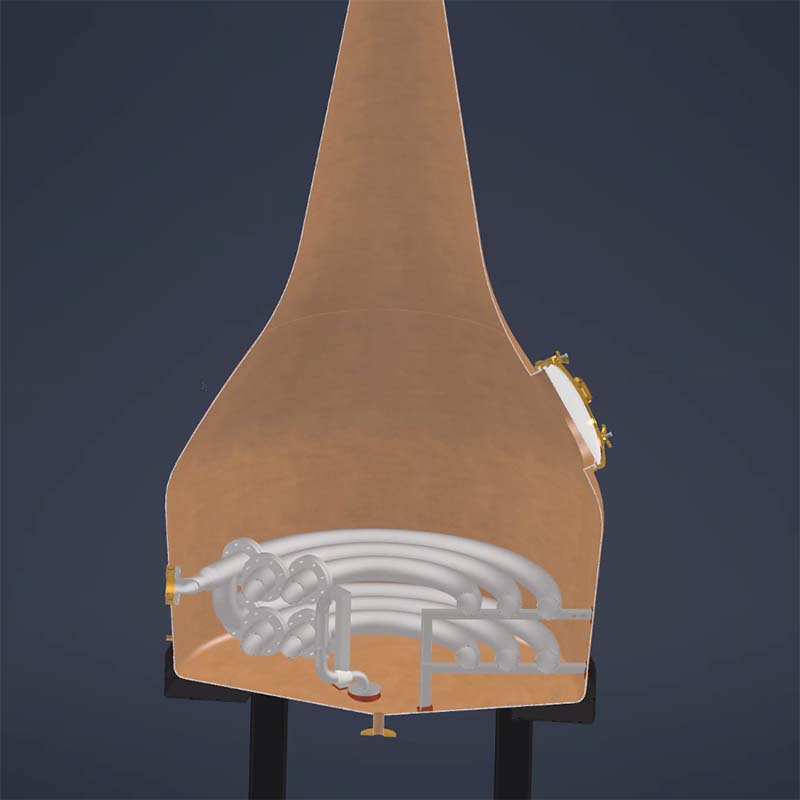

why geodesic?

copper contact

The larger surface area and volume of copper all leads to more copper contact with the spirit. More copper contact removes sulphurs and has a catalyst role in converting thiols and mercaptans to usually less pungent compounds. The flat sides encourage high reflux levels and enhances the removal of these compounds, promoting the development of the fruity, estery clean spirit.

"I’ve discussed with our man in charge of the copper stills Derek Brewster, he’s been building stills for close to 40 years now and in his spare time he travels the UK fixing up all the classic steam train engines. He says he can make this shape, we could have a mixture of folded edges then the pieces would weld together like a jig saw." Garry Frazer, Speyside Copper Works.

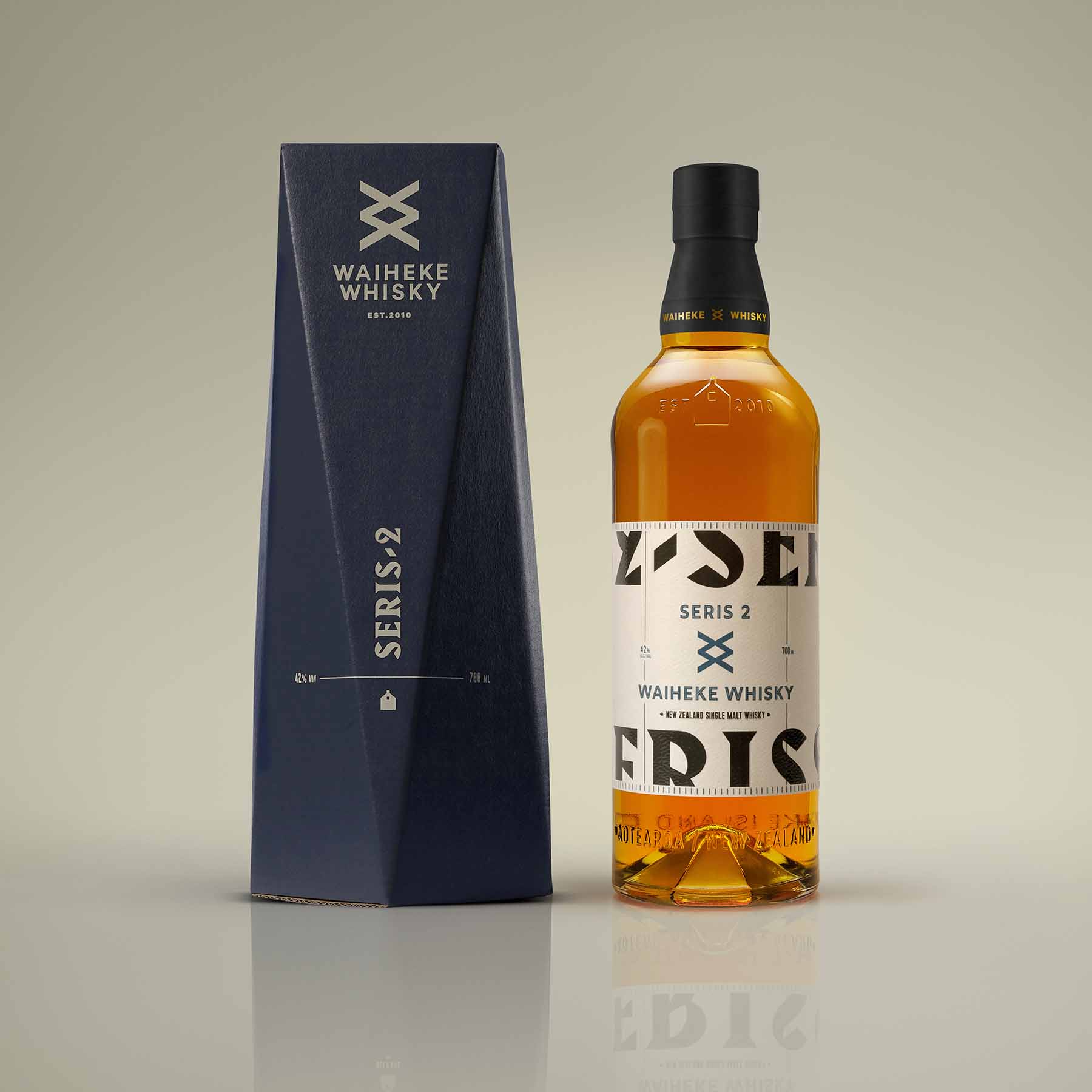

WASH STILL 3000l

The team decided on a tadpole shaped still for the wash, predominantly for our peated character. Less reflux and a faster run with the lyne arm is pointed downwards allows more of the peaty flavour to run into the low wines.

SPIRIT STILL 2500l

The spirit still retains the geodesic shoulders and is designed for more reflux, with a hourglass neck and horizontal lyne arm.

sustainable

electric fired steam

The wash still has 2 sets of steam coils, alowing for rapid heating of the wash. These are supplied by 3x electric steam fired boilers, powered by 100% renewable energy

Prime energy

100% Carbon Zero Power

We are committed to our carbon zero goal and have partnered with Prime Energy to supply our power for the stills and the brewhouse.

evolution of the species

V.I.T.R.Io.l MK2

Here are the shoulders of the spirit still talking shape. After consutation with Garry and Derek we have incorporated the design in to the spirit still. .

tadpole wash still

Here the shoulders of the wash are nearly complete. Its 2m diameter at the base and when complete stands 5m high. It is designed for minimal reflux for a peaty low wine.

the future of steam

electric steam boilers

The use of fossil fuels in the distillery industry is a dirty secret. Oil, gas and diesel still make up the vast majority of energy sources for heating water and the stills. We chose electricity, 100% renewable, sourced from hydro and geothermal as our power source. Our first stills, VITRIOL1&2 were direct electric fired, using heating coils.

Our New Stills, VITRIOL 3&4 use electric fired steam, again 100% renewable energy. The electric fired boilers, generate 570kgs of steam and hour at nearly 95% efficiency.

Waiheke Whisky is comitted to sustainable practice. from recycled glass in our bottles to 100% renewable ennergy to fire the brewhouse and stills.